The HGV air braking system is a sophisticated piece of engineering, creating crucial stopping power for heavy vehicles, improving safety with evenly distributed braking for rigid and articulated vehicles.

HGV Air Braking System

One of the most crucial parts of an HGV truck is its air braking system. This type of brake can be traced back to George Westinghouse who developed it in the 1800s for trains, but quickly realised that this technology could also be applied to trucks. It became popular within these vehicles from the early 20th century onwards and has been used ever since!

What is an Air Braking System?

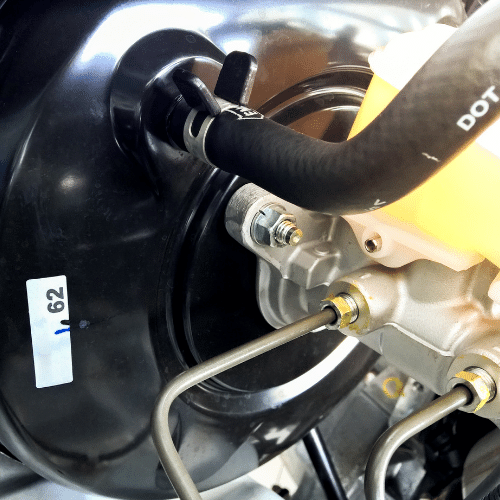

An air brake or a compressed air brake system is a type of friction brake for vehicles, in which compressed air pressing on a piston is used to apply pressure to the brake pads needed to stop the vehicle.

Air brakes are used in large heavy vehicles, particularly those having multiple trailers which must be linked into the brake system, such as trucks, buses, and trailers.

The system consists of service brakes, parking brakes, a control pedal, and air storage tanks.

For the parking brake, there’s a disc or drum brake arrangement which is designed to be held in the ‘applied’ position by spring pressure.

Air pressure must be produced to release these “spring brake” parking brakes.

For the service brakes “the ones used while driving for slowing or stopping” the brake pedal is pushed down, routing the air under pressure (approx 100–120 psi or 690–830 kPa or 6.89–8.27 bar) to the brake chamber, causing the brake to be engaged.

Most types of HGV air brakes are drum brakes, though there is an increasing trend towards the use of disc brakes to perform the braking of a HGV.

The air compressor draws filtered air from the atmosphere and forces it into high-pressure tanks at around 120 psi (830 kPa; 8.3 bar).

A sudden loss of air pressure would result in full spring brake pressure immediately applying the brakes.

Most HGV vehicles have a gauge incorporated on the driver’s dashboard, indicating the amount of air pressure for safe vehicle operation, and usually has warning sounds or lights to indicate low air pressure.

Setting the parking or emergency brake releases the pressurised air in the lines between the compressed air storage tank and the brakes, thus allowing the spring-actuated parking brake to be engaged.

The supply system compresses, stores, and supplies high-pressure air to the control system as well as to additional air-operated auxiliary truck systems gear shift control, clutch pedal air assistance servo, etc.

A compressed air brake system is divided into a supply system and a control system.

HGV Air Braking Supply system

- The air compressor is driven by the engine either by crankshaft pulley via a belt or directly from the engine timing gears.

- It is lubricated and cooled by the engine lubrication and cooling systems.

- Compressed air is first routed through a cooling coil and into an air dryer which removes moisture and oil impurities and also may include a pressure regulator, safety valve, and smaller purge reservoir.

- As an alternative to the air dryer, the supply system can be equipped with an anti-freeze device and oil separator.

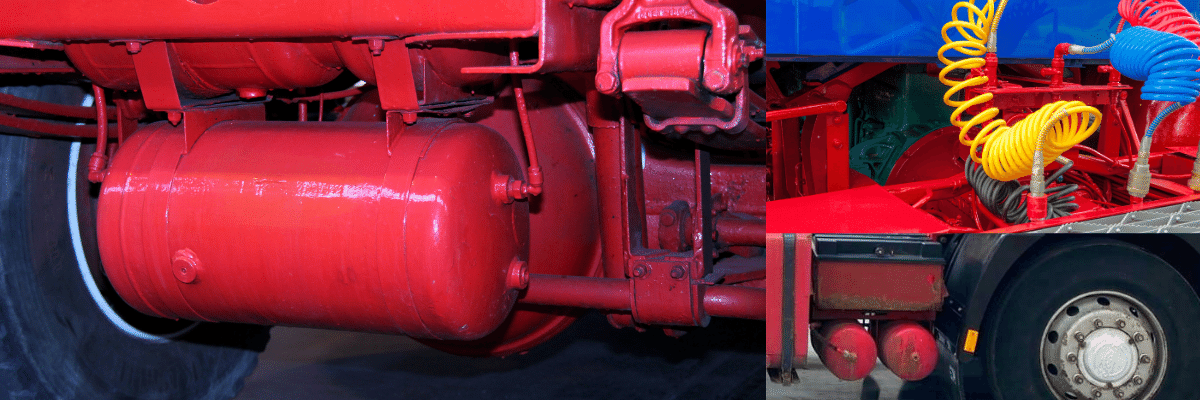

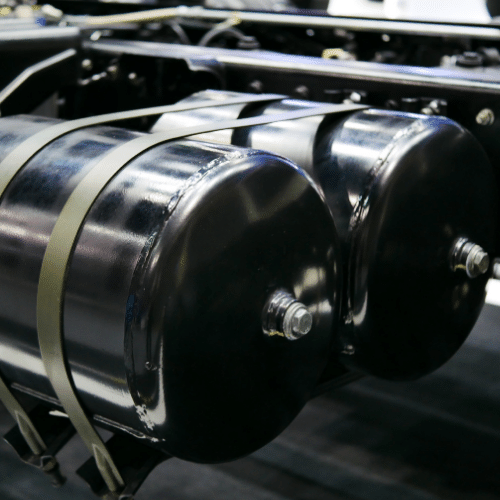

- The compressed air is then stored in a reservoir “also called a wet tank” from which it is then distributed via a four-way protection valve into the front and rear brake circuit air reservoir, a parking brake reservoir, and an auxiliary air supply distribution point.

- The system also includes various checks, pressure limiting, drain, and safety valves.

- Air brake systems may include a wig wag device which deploys to warn the driver if the system air pressure drops too low.

HGV Air Braking Control system

- The control system is further divided into two service brake circuits, the parking brake circuit, and the trailer brake circuit.

- The dual service brake circuits are further split into front and rear wheel circuits which receive compressed air from their individual reservoirs for added safety in case of an air leak.

- The service brakes are applied by means of a brake pedal air valve which regulates both circuits.

- The parking brake is the air-operated spring brake type where is applied by spring force in the spring brake cylinder and released by compressed air via a hand control valve.

- The trailer brake consists of a direct two-line system: the supply line (marked red) and the separate control or service line (marked blue).

- The supply line receives air from the prime mover park brake air tank via a park brake relay valve and the control line is regulated via the trailer brake relay valve.

- The operating signals for the relay are provided by the prime mover brake pedal air valve, trailer service brake hand control (subject to local heavy vehicle legislation), and the prime mover park brake hand control.

Air Brakes

Hydraulic Brakes

Air brakes are used as an alternative to hydraulic brakes which are used on lighter vehicles such as cars and small vans.

Hydraulic brakes use a liquid (hydraulic fluid) to transfer pressure from the brake pedal to the brake shoe to stop the vehicle.

Air Brakes Advantages for HGV Vehicles

- The supply of air is unlimited, so the brake system can never run out of its operating fluid, as hydraulic brakes can.

- Minor leaks do not result in brake failures.

- Air line couplings are easier to attach and detach than hydraulic lines.

- Air brake circuits on trailers can be easily attached and removed by operators with the use of flexible air lines.

- Air not only serves as a fluid for transmission of force, but also stores potential energy.

- Air brake systems include an air tank that stores sufficient energy to stop the vehicle if the compressor fails.

- Air brakes are effective even with considerable leakage, so an air brake system can be designed with sufficient “fail-safe” capacity to stop the vehicle safely even when leaking.

Thank you for reading this Article “HGV Air braking system” if you would like to leave a comment of your views please do so below.